this version features a custom heatsink combined with the bottom plate, suitable for aluminium CNC milling. the construction provides a better heat dissipation compared to the DIY (FFF) version. see all details in the readme. |

2 years ago | |

|---|---|---|

| assets | 2 years ago | |

| diyplus | 2 years ago | |

| fff | 2 years ago | |

| .gitattributes | 2 years ago | |

| .gitignore | 2 years ago | |

| README.md | 2 years ago | |

README.md

nakamochi 3D designs

at the moment, there's only an FFF (Fused Filament Fabrication) design suitable for 3D printing at home in the fff directory.

all design sources are made in freecad no older than v0.20. a stock installation of freecad should be sufficient but you might want to install fasteners workbench if working on a design assembly.

fff

the main file is in fff/provcase.FCStd. "provcase" stands for "provisional case" because it is still unclear whether this will be a final design.

the project contains all the parts to make a full assembly with the following BOM:

- raspberry pi 4 model b

- waveshare 4.3inch DSI LCD

- joi-it armor "block" heatsink

- sandisk portable 1TB SSD sdssde30-1t00

all object constraints reference an embedded spreadsheet params to avoid

topological naming problem.

prefer constraining against datum objects instead of faces and other elements produced

directly from sketches like pads.

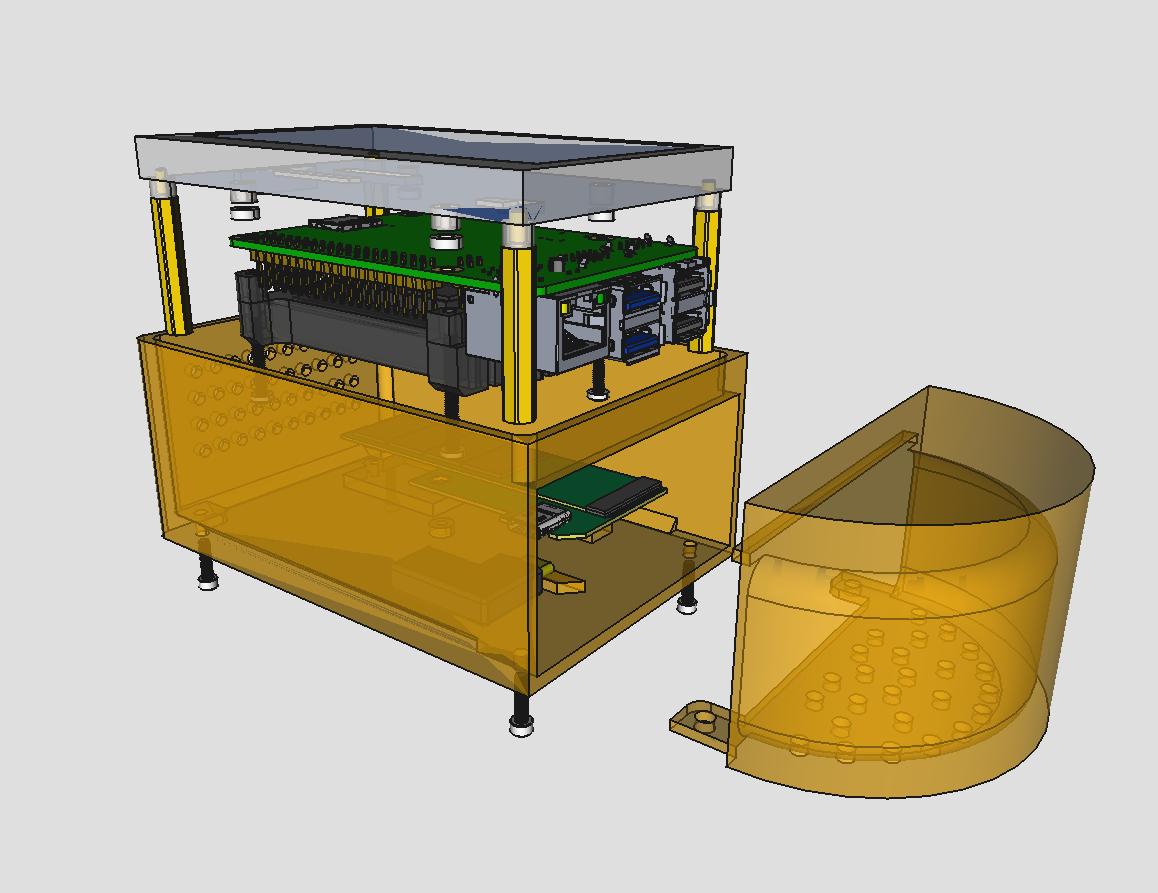

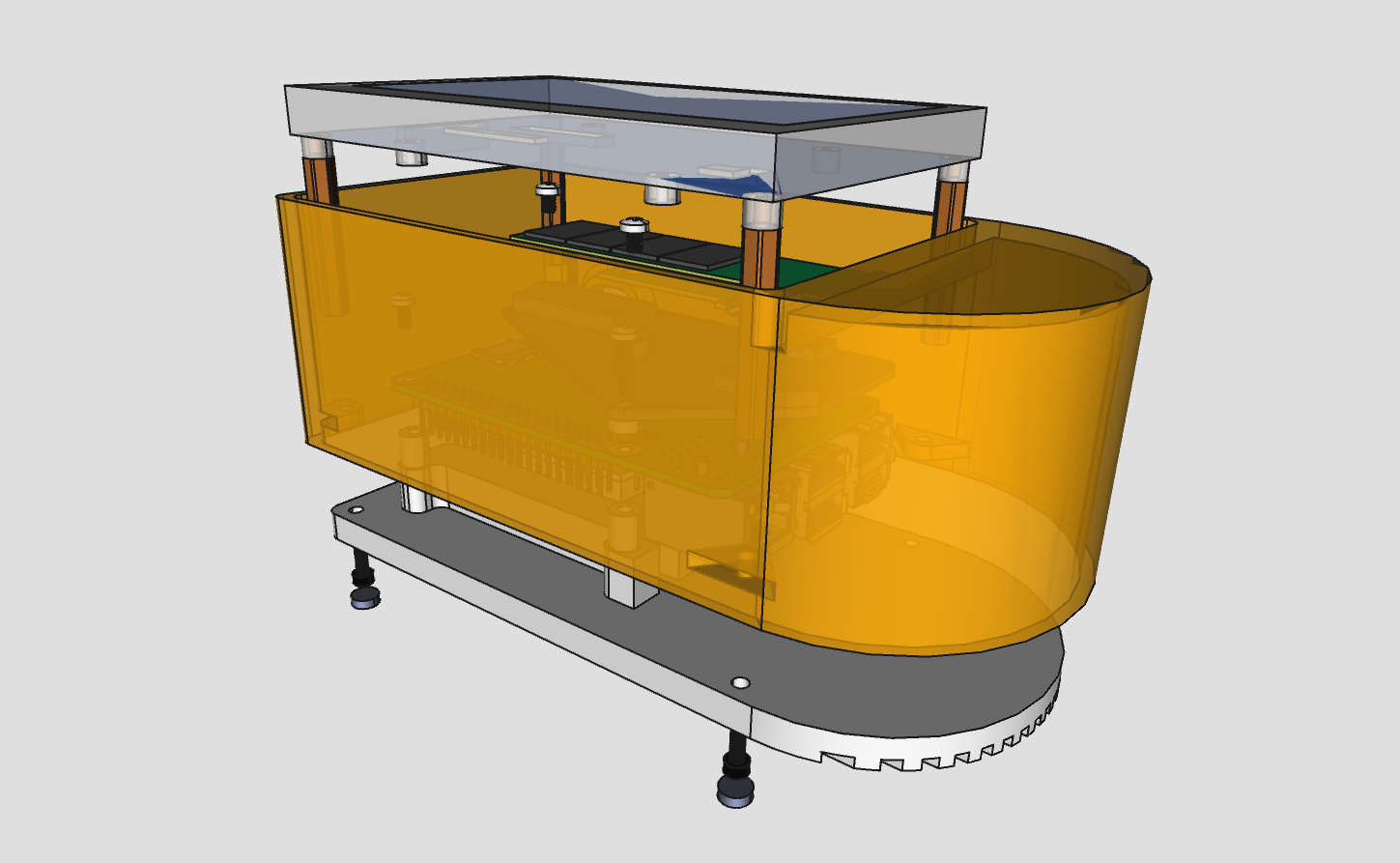

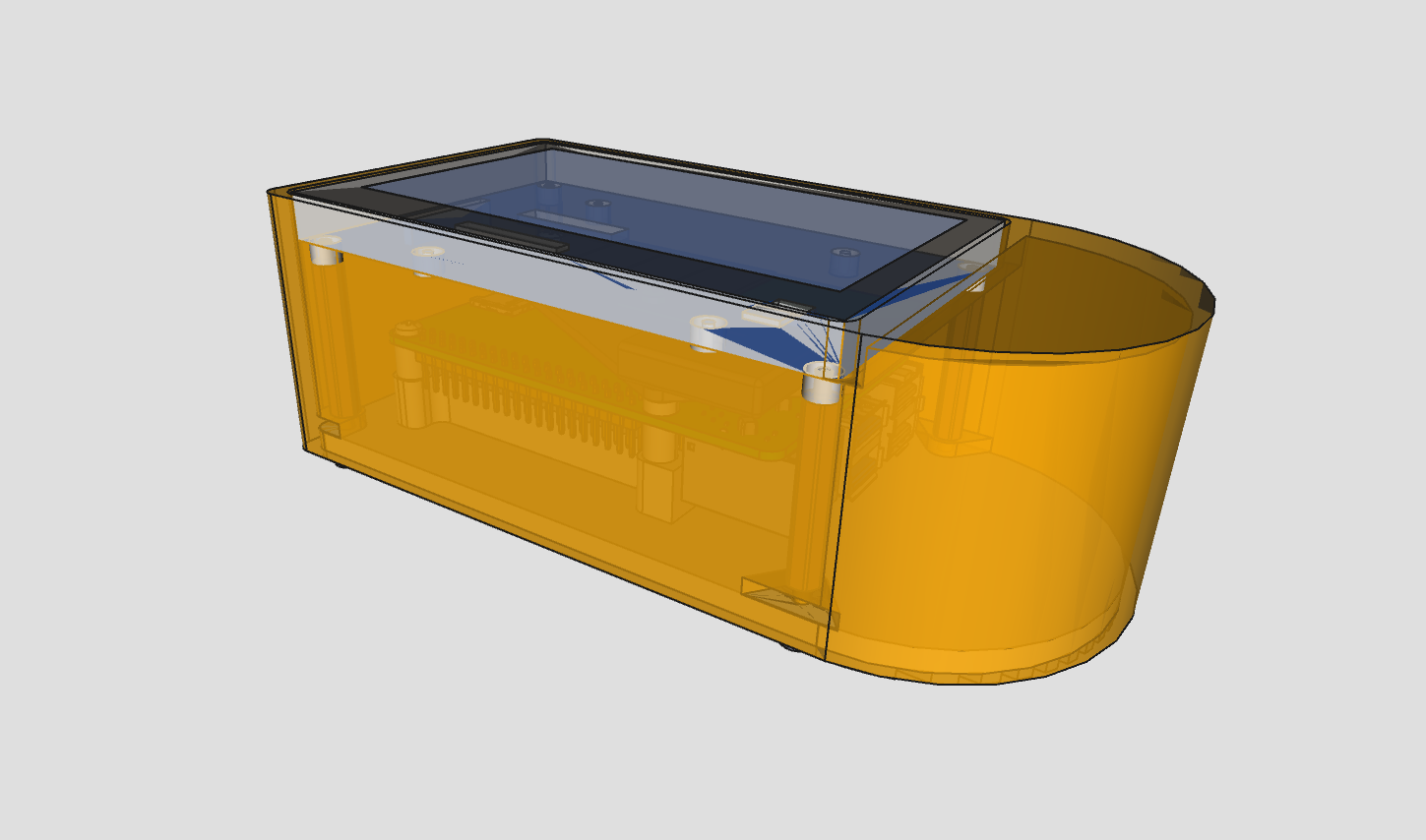

finally, the fff/provcase-assembly.FCStd file contains

an "assembly" group. this is simply a collection of parts composed together to help

visualize how and whether all of them fit well together. it links to the provcase.FCStd,

so you'll need both files. this assembly group calculates all placement offsets from

asmsheet spreadsheet. here's how the assembly looks like:

the "assembly" std part has a custom property "view" with two options: exploded and assembled. the property is configured from the same asmsheet.

3D printing the parts

TODO: insert here acceptable 3D printer specs and an assembly guide

DIY+ (plus)

this version features a custom heatsink combined with the bottom plate, suitable for aluminium CNC milling. the construction provides a better heat dissipation compared to the DIY (FFF) version.

|

|

|

|

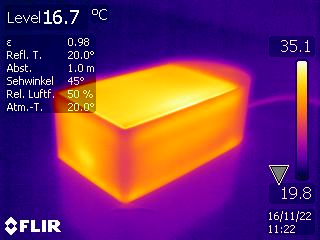

the baseplate serving as a heatsink brings down the main CPU temperature

from around 70℃ to 50℃. when measured externally while doing bitcoin initial

blocks download, an IR camera showed around 36℃.

the baseplate serving as a heatsink brings down the main CPU temperature

from around 70℃ to 50℃. when measured externally while doing bitcoin initial

blocks download, an IR camera showed around 36℃.

the main file diyplus.FCStd contains all parts as well as the assembly. other files in the diyplus directory are exports from the main file, such as baseplate DXF, STL, STEP and drawings.

a complete assembly BOM is as follows.

off the shelf parts

- raspberry pi 4 model b

- waveshare 4.3inch DSI LCD

- sandisk portable 1TB SSD sdssde30-1t00

- 90 degree angle USB-C adapter 3.1 gen 2, 10Gbps

- adhesive gasket/seal tape for LCD, 1mm thick, 10mm width, L370mm

- 3 thermal pads 1.5mm thick, 424mm sq total area - see baseplate drawing

- 7 screws M2.5 L10mm

- 4 adhesive bottom pads Ø5mm, 3mm+ thick

other parts, harvested from the above list:

- 2 self-tapping screws 2.9mm L3mm (from the SSD)

- 1 screw M2.5 L5mm (from the LCD)

- 4 PCB standoffs M2.5 L30mm (from the LCD)

custom parts

- baseplate, CNC milled from aluminium

- enclosure box, 3D-printed

- SSD support plate, 3D-printed

- 3 spacers Ø3mm hole, 2.4mm thick

TODO: assembly instructions

assets

various files are placed in the assets to use in an assembly composition. for example, you'll find a 4.3inch display, raspberry pi 4 and a heatsink in there.

when creating a design assembly, make a new std part group and import desired assets into it. if an asset is in a freecad file format, open the file and drag&drop the top level object into the newly created std part. then close the original file ignoring the changes.